Cell production process, the effect of screen printing will directly affect the conversion efficiency of the battery, the printing core is the aspect ratio of the silver paste after printing. Therefore, the screen, silver paste and squeegee must be kept innovative, when the preparation of higher requirements of screen printing

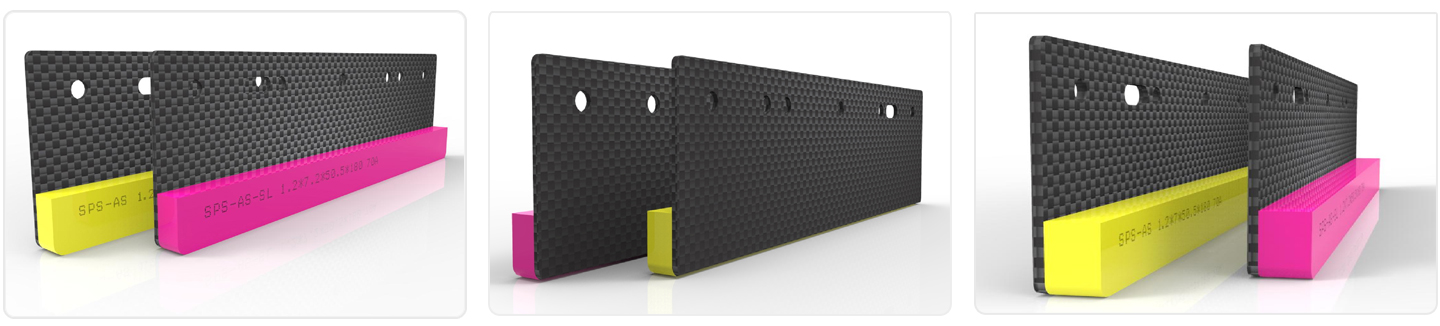

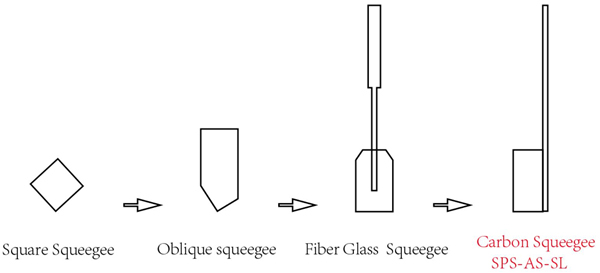

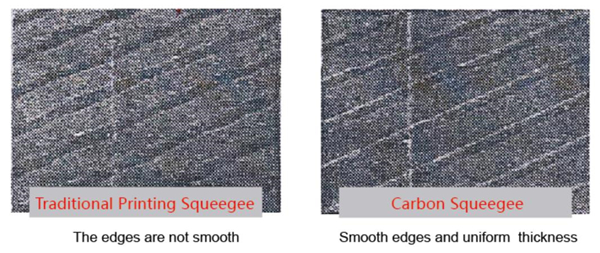

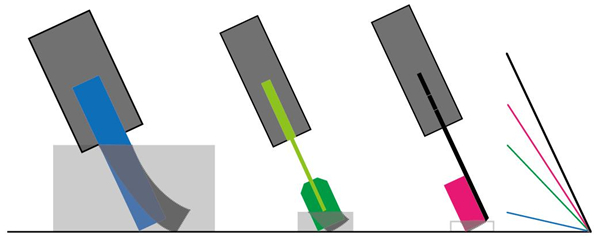

Development of photovoltaic squeegee:Just ten years, the gate line requirements more and more fine, has been from the initial 60um into the current 18um; followed by the squeegee replacement (as shown below), now HANZE LTD-FBA SQUEEGEE is more and more popular!

SPS-AS-SL's core strengths are:

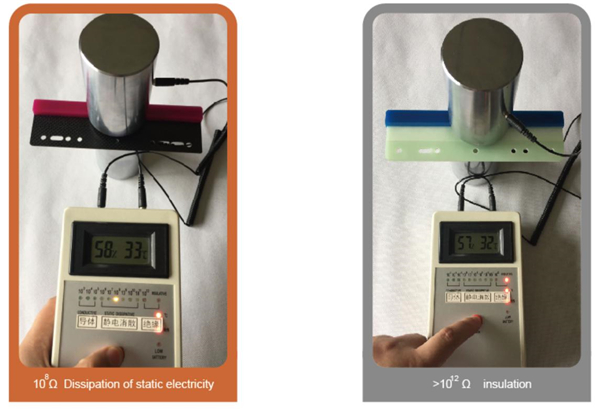

1.1 Electrostatic Dissipation Benefits

During the printing process, squeegee, screen, ink,silicon wafer friction static electricity is easily generated and static electricity accumulates to a certain voltage difference.Can cause silver particles, small particles, flying ink, etc.

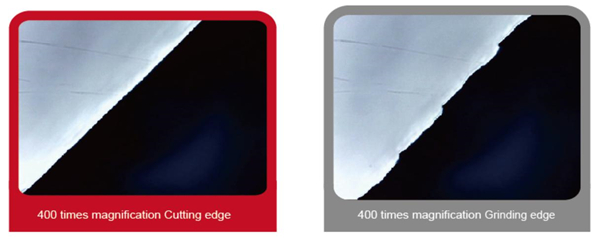

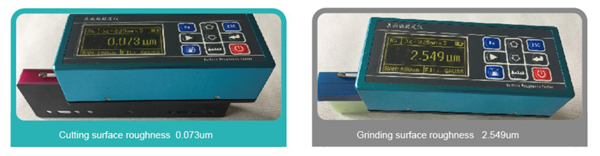

1.2 Advantages of cutting type squeegee

The blade is smoother, and the ink on the screen is cleanerSharper edges for finer lines

1.3 After testing, the support plate squeegee saves 8% of the silver paste compared to the traditional squeegee!The traditional squeegee printing process is easily deformed, the stable printing pressure and the printing angle cannot be maintained, and silver wire breaks easily.The operator must increase the printing pressure and reduce the printing angle to reduce the breakage, which will increase the ink consumption.

1.4 High print times

The surface roughness of the bottom of the squeegee is low and the surface area is small, reducing the area of the contact solvent ,solvent corrosion squeegee speed is reduced.Squeegee is not easy expansion and wear.Japan's latest polyurethane formula, more solvent-resistant, more wear-resistant.

1.5 Unilateral design

Less solvent etched area

Smaller deformation area

Maintain stable printing pressure and angle for a long time

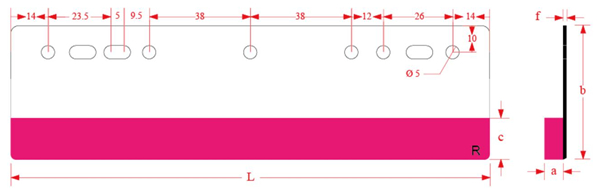

2.Size and hardness

2.1 Size

Code | L | a | b | f | c | d | R |

Size(mm) | 180 | 7.2 | 50 | 1.6 | 15 | 20 | 2.5 |

Tolerance(mm) | ±1 | ±0.3 | ±0.5 | ±0.2 | ±0.2 | ±0.5 | ±0.5 |

2.2 Hardness

Different hardness corresponds to different colors

Polyurethane squeegee type AS MADE IN JAPAN | Yellow—62±3 | Hardness Tester TYPE-A GS-719N |

Rose red—72±3 |

3.1 Material

3.2 Polyurethane rubber

Polyurethane rubber made in Japan

3.1.1 Physical properties

Project | Unit | Squeegee type AS | |

colour | Cyan 62A | Green 72A | |

hardness | JIS-A | 62±3 | 72±3 |

100% stretchability | MPa | 2.52 | 2.81 |

200% stretchability | MPa | 3.72 | 4.20 |

300% stretchability | MPa | 6.50 | 5.65 |

Maximum stretching | MPa | 35.1 | 22.1 |

Tensile limit | % | 632 | 532 |

Breaking strength | KN/m | 45.4 | 58.8 |

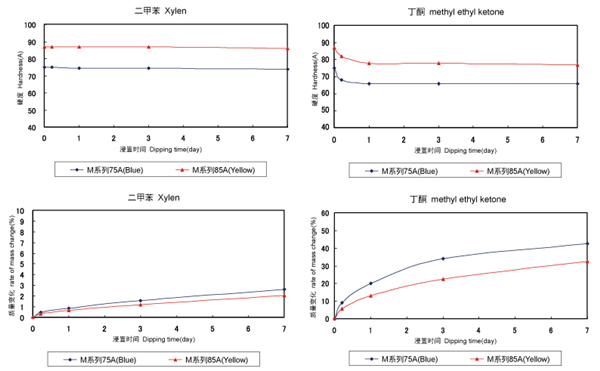

3.1.2 Chemical solvent resistance

Test time: 7 Days

Test solvent: xylene, methyl ethyl ketone

Test items: hardness change, quality change

3.2 Carbon

The high quality carbon has uniform thickness, good elasticity and chemical resistance,conductivity.

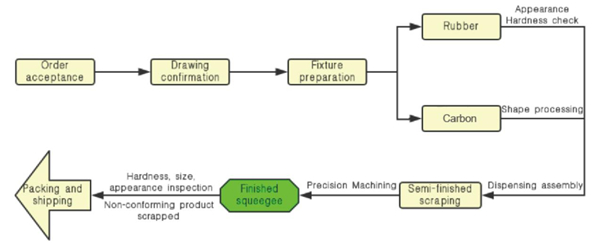

4.Production process

The entire process from receiving an order to shipping

5.Packaging, storage

5.1 packaging

Paper package

20Pcs/Box

5.2 storage

①Store indoors at 40℃ or lower, do not store in high temperature and high humidity, direct sunlight and ultraviolet radiation. (Recommended storage conditions: 23℃±2℃, humidity 60% or lower)

②Do not store near heat-generating equipment or dusty places.

③It is forbidden to bend and press, stack it straight, stack no more than 20PCS.

④The scraping rubber is stored at a low temperature for a long time, and can not be used immediately after being moved to the workshop. It should be placed at 25℃for more than 3 hours before use.