V mesh is specialized in application of electronic industry. At present it is widely used in demanding screen printing areas like PCB(printed circuit board), TSP(touch screen panel) and display, decorative glass, Solar power panel printing. Rely on its higher modules and excellent elongation,V mesh reached high standard parameters of accurate mesh opening, high tensile strength and smooth ink release; Less tensile loss after stretching brings the uniformity of deformation on warps and weft direction and more stable dimensional changes; Special surface treatment of impurities removal extends the lifetime of printing stencil by increasing the fastness of emulsion; Diversity of mesh-counts and width options, sufficient production capacity supports

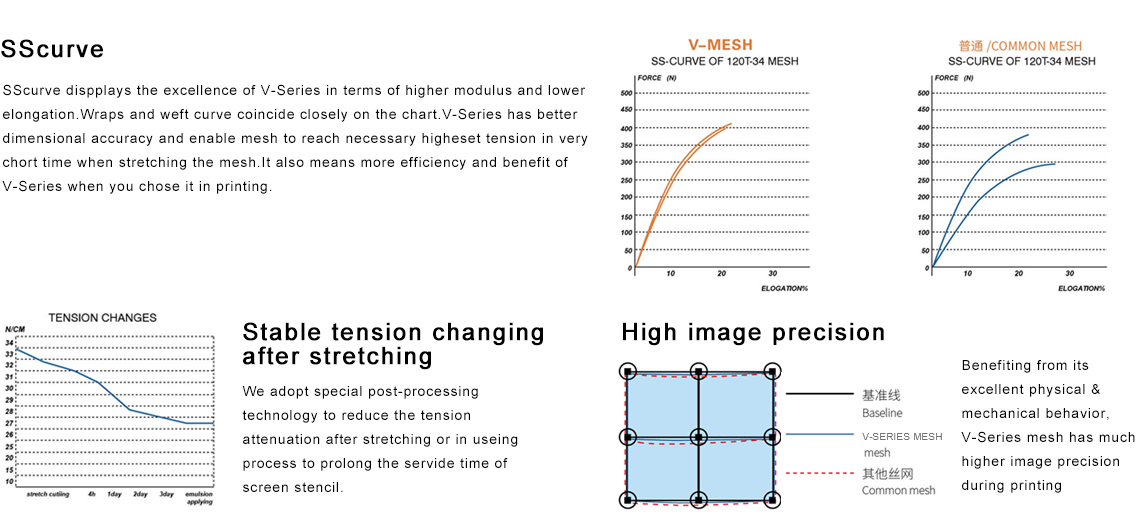

Higher modulus & excellent elongation

The most advanced finishing process reduce the tensile changing and prolong the lifetime of mesh/bolting cloth. Each warp is in even tensile under control of TAC technology. This process maximize the tensile strength of mesh/bolting cloth.

Core-shell structure yarn material & high resistance to scratch

V mesh is made of qualified yarn material from professional supplier who is the giant fiber manufacturer. By long-term collaborative R&D, the yarn has high tensile strength which is the key factor to stability and higher modulus of mesh/bolting cloth. Meanwhile yarn's core- shell structure increase wearing resistance.

Precise mesh opening demension & smooth ink permeability

Accurate reeds (spare parts) and microcontroller of looms ensure the uniformity of mesh opening in both warp weft direction. Lower dyne of mesh surface represents the smooth permeability of ink.

MESH COUNT | DIAMETRER | OPENING | OPEN AREA | THICKNESS | INK VOLUME | Recommended Max Tensile | ||

Per cm | Per inch | μm | μm | % | μm | g/m² | N/cm | |

32T | 32 | 80 | 100 | 210 | 45 | 185 | 83 | 45 |

36T | 36 | 90 | 90 | 186 | 45 | 166 | 74 | 43 |

40T | 39 | 100 | 80 | 172 | 46 | 134 | 61 | 41 |

43T | 43 | 110 | 80 | 145 | 40 | 151 | 61 | 44 |

48T | 48 | 120 | 71 | 137 | 42 | 121 | 50 | 30 |

77T | 77 | 195 | 55 | 65 | 25 | 87 | 22 | 43 |

100T | 100 | 250 | 39 | 57 | 31 | 62 | 19 | 35 |

110T | 110 | 280 | 34 | 53 | 34 | 53 | 18 | 28 |

120S | 120 | 300 | 31 | 49 | 33 | 48 | 16 | 25 |

120T | 120 | 300 | 34 | 47 | 30 | 52 | 16 | 29 |

130T | 130 | 330 | 34 | 39 | 26 | 52 | 14 | 31 |

140S | 140 | 350 | 31 | 37 | 25 | 47 | 12 | 27 |

140T | 140 | 350 | 34 | 31 | 18 | 53 | 9 | 35 |

150SS | 150 | 380 | 27 | 36 | 29 | 42 | 12 | 20 |

150S | 150 | 380 | 31 | 31 | 21 | 48 | 10 | 29 |

165S | 165 | 420 | 27 | 29 | 24 | 41 | 10 | 24 |

165T | 165 | 420 | 3 | 23 | 15 | 50 | 8 | 26 |